Biogas Systems

Our range of biogas and leachate management systems are designed and manufactured to the highest standards.

Get in Touch

Reach Out To Our Team

Biogas Systems

We use proven methodologies to quantify and report Greenhouse Gas (GHG) emissions reductions at landfills, piggeries, wastewater treatment plants and the like. Our GHG reduction projects are also designed to acquire the data necessary to successfully demonstrate acceptable destruction of gases and volatile organic compounds. Ancillary controls have also been recorded to demonstrate odour reductions of greater than 98%.

We provide a range of equipment for biogas and leachate management:

• Mobile elevated flares (RF Range)

• Low-Cal High Temperature HT flares (Low Cal Range)

• HT Enclosed Ground Flares

• Leachate treatment systems.

The main advantages of our RF Range include:

All our flaring systems can be provided with a range of remote access control, telemetry and range of monitoring instrumentation.

We offer informed opinion on developing projects that deliver verifiable emissions reduction in the following industries:

• Mining

• Landfill

• Piggeries

• Wastewater Treatment Plus

Biogas Systems: RF Range

Our RF Range open flare stacks provide a degree of control over the combustion process in an elevated flame burner. The RF Range are solar powered flare, perfect for use at anaerobic digestion lagoons, landfills and the like. These flares can be simply connected to any biogas connection line or well for the combustion and destruction of dangerous greenhouse gas without the need for blowers that require an external power source.

Our RF Range is designed for effective combustion and re-ignite over a range of flows, typically from 20-100 m3/hr. Flame temperatures range between 450 to 900 degree C depending on up the methane concentrations, flow rate and wind conditions. Lower flow rates can be accommodated if methane concentrations are adequate for flame stability.

Biogas Systems: Low Cal and HT Enclosed Ground Flare

Our Low Cal Range flare is designed specifically to address the problem of combusting gases with low calorific values, or heat contents. The optimisation of combustion control techniques ensures that heat-loss is minimised, whilst air and gas mixing is maintained at a very high level. The Low Cal Range is designed to operate at flow ranges between 50 to 1,000m3/h at with as little as 5%v/v methane in air, subject to the concentration of other gases in the fuel mix, such as carbon dioxide and air.

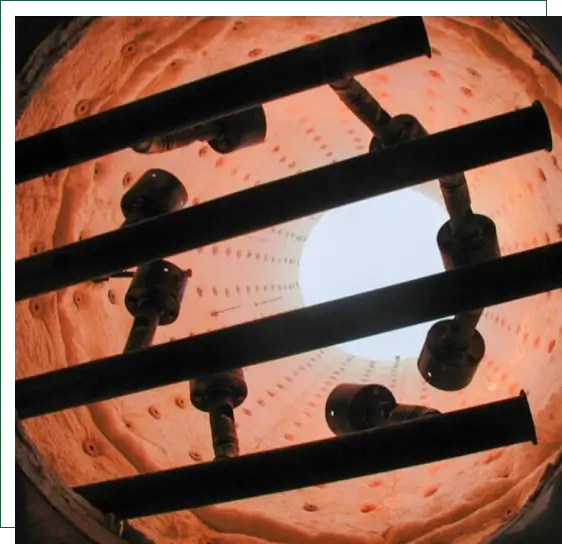

Our HT Enclosed Ground Flare provides a competitively priced enclosed flare option to meet growing public concern and greenhouse gas emissions standards. These flares are fully enclosed with no visible flame while controlling heat loss to the environment and holding the design temperature for a specified period (the retention time).

The HT Enclosed Ground Flare can be built to be modular and expandable to address growing or diminishing gas production, thereby allowing a staged gas collection approach. The HT Enclosed Ground Flare are custom built to accommodate flow ranges between 100 to 6,000m3/hr at retention times between 0.3 and 0.6 seconds.

Biogas Systems

Case Studies

Landfill Rehabilitation and Redevelopment

Core Environmental Projects were initially engaged to prepare a concept gas collection and interception design based on existing landfill gas investigations and risk assessments. Early in the review, Core identified several areas of opportunity where the landfill gas risks could be downgraded via detailed landfill gas investigation to support the completion of a quantitative landfill gas risk assessment.

“Core EP’s expertise and open communication were crucial in navigating legislative requirements and guidelines, ensuring safe and compliant project delivery.”

B2B

“Core-EP ensured the remediation design was fit for purpose and worked along installation contractors to establish the most efficient construction methods. The works provided a pathway for regulatory approval and enabled a simple sales and building process.”

Parcel Property

“Core-EP's installation of a landfill gas interception system provided residents with peace of mind regarding human health risks. Energetic, dedicated and knowledgeable team. Highly recommend for their expertise.."

TW Projects

“Provided a groundbreaking solution.. Core-EP was..crucial for achieving final occupation of our residential complex. Expertise and dedication were evident from our first meeting, and their ability to collaborate seamlessly with all stakeholders was outstanding.”

Core Developments

“Our experience with Core-EP was outstanding. They conducted a thorough environmental assessment for 12 individual landowners, addressing soil and vapor conditions with expertise and precision. Professional, knowledgeable, and attentive to our unique needs. Core-EP’s meticulous planning and focus on end results streamlined the process and expedited regulator approvals. Highly recommended for their expertise and efficiency.”

Mia Projects

“Core-EP's solutions profoundly improved our workflow and efficiency by addressing the environmental concerns. Since partnering with Core-EP, we've gained valuable insights into managing environmental issues, greatly enhancing our project outcomes.”

Fathom